Digital Assembly Management System solution helps the manufacturing industries by providing the top 11 features to work rapidly and efficiently. The solutions connect people with technology to help them understand operations and respond faster. It also provides a plant floor for seamless management across a company.

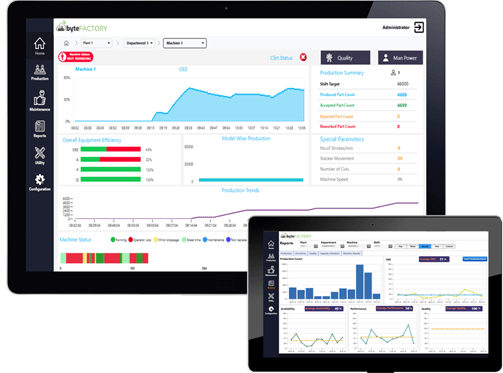

- Digital Assembly OLE Analytics

- Digital material entry with RFID/Barcode sticker mapped with material attributes such as part No, Model NO, worker ID, etc.

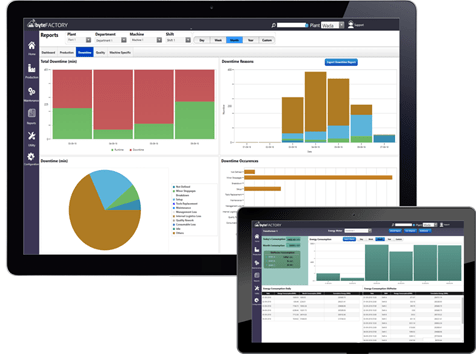

- Station wise automatic talk time capturing downtime reasoning using industrial HMI’s and assembly line performance analysis.

- Configurable station wise KPI’s and reports for station wise, shift wise, operator wise, model wise and periodical

- Shop-floor ANDON display for better assembly line performance visualization and quick decision making.

- Process monitoring and interlocking system

- Assembly station Vs. Model detection, assembly line interlocking and superior access control for interlocking retrieval mechanism.

- Process monitoring and anomaly detection, assembly line interlocking and superior access control for interlocking retrieval mechanism.

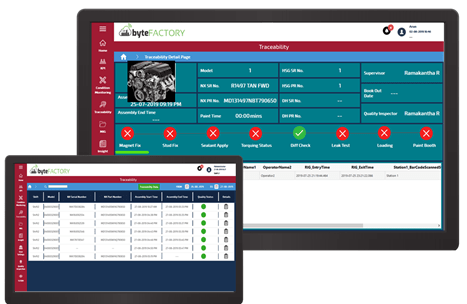

- Material traceability- station wise parts foot print capturing w.r.t production, process, quality and safety.

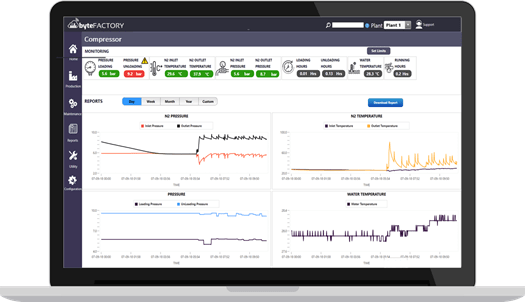

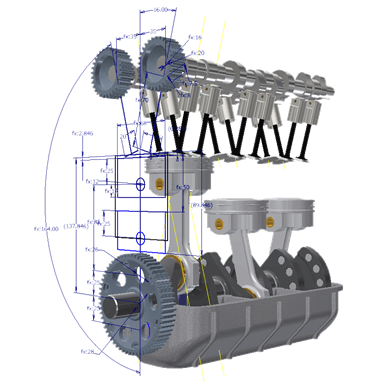

- Condition Monitoring and predictive maintenance

- Condition Analysis and Threshold based alerts and configurable threshold limit- setting threshold limit (Min and Max value for each parameter)

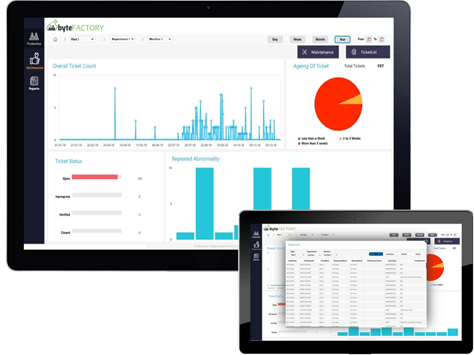

- Mobile app based preventive maintenance instruction and execution.

- Automatic machine-initiated maintenance request by for faults and alerts. Trading system to view a list of issues and follow up the progress in maintenance issues.

- Track and Trace

- Integration of assembly line utility tools such as nut runner, digital gauges, poke-yoke system and automated remote configuration based on in-line assembling models.

- Digital sub assembling component validation against assembly parts RFID/Barcode scanner.

- Integration with ERP tool to generate unique ID number and stamping new part no using engraving or punching machine.

- Design for Assembly ( DxA)

- Integration of engineering design tools for centralized design management

- Assembly manufacturing information guidelines (MIG) for seamless assembly engineering instruction

- Digital MIG visualization with IIoT system for integrated assembly engineering management.

- Quality Management System

- Digital quality inspection checklist to capture the quality related checks across assembly lines.

- Why-Why and 8D Analysis provides better visibility and quality related issues & activities.

- Online SPC Analytics by integrating assembly line inspection and testing station to capture and provide real-time quality Cp and Cpk analysis.

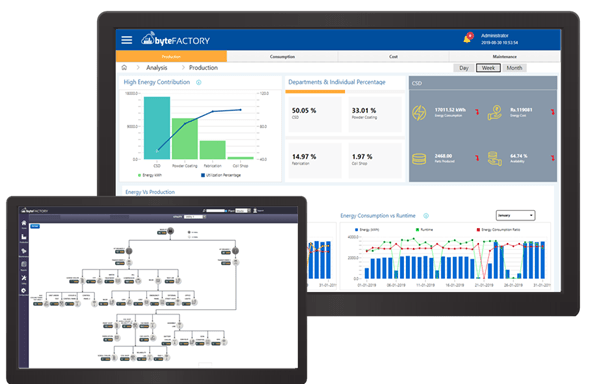

- Energy and Utility analytics

- Coverage of Energy HT/LT panel to Machine level and single line diagram representation of factory from substation to end asset

- Utilizes consumption and Condition Monitoring – Water, Air, Gas, Thermal, etc.

- Configuration reports and trends –Energy and Utility Consumption trend analysis and Reports – For hours, shits based, daily management and by machine basis.

- Augmented Reality for Digital Maintenance

- Guided troubleshooting for demo fault identification with the help of augmented 3D technical manual for service personnel.

- Step by step instruction with safety and tools instruction and augmented tutorial for assembling and disassembling.

- Annotation of the parts for ease of identification and visualize AR View-Zoom In and out control bar

AR based product pre-buying customer experience mobile app for Form – Fit – Function

- Virtual Reality Experience

- Safety and Health training using VR experience and provide skill rating based on the training offered to workers.

- VR Experience based Remote expert support on critical maintenance and service issue.

- Provides VR experience for digital assembly line visualization overlapping the IoT Meta data.

- Machine Vision for digital inspection

- Photometry-based cameras provides automated visual inspection solution and Track pass/fail data and trends.

- Detects the slightest, low-contrast variation in assembly parts and surfaces

- Assembly Parts Verification: Component Presence, Position, internal screws and components.

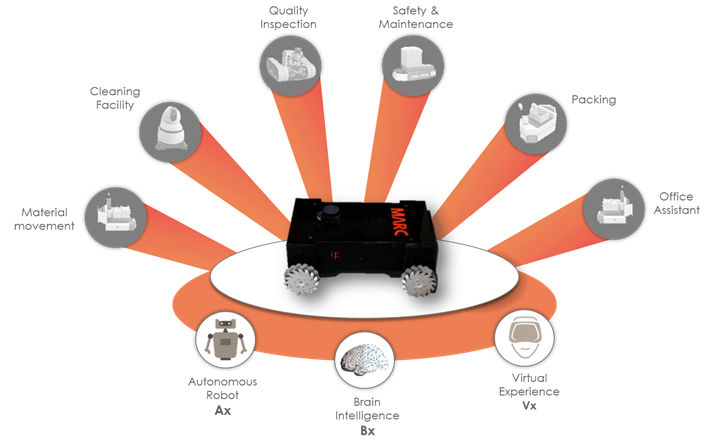

- Autonomous Robot – MARC

- Industry 4.0 aligned Autonomous Robots are trained to handle operational and material supply task.

- IT will gather and process information to instant decision making and it help in reducing the labour work pressure and increase the productivity of the entire manufacturing industry.

The edge devices required for connecting the machines from the shop floor to the top floor can be purchased from the e-commerce marketplace.

In Maxbyte, we provide the diploma in industrial digitization to upskill all roles from shop floor to top floor in the manufacturing industry and efficient digitization implementation.

Expert services for your digital transformation solutions can be hired from a talent on-demand platform.

Maxbyte has implemented Digital Assembly Management System for various industries and demonstrated business value to the customers, and also, customers started to realize their benefits.

To know more – Contact us or Book an appointment.