Digital technologies have been always changing, and organizations want to stay ahead of the curve to gain a competitive advantage. Due to this relentless technological advancement, many Industries transformed to Industry 4.0 and efficiently improved their production.

The IoT enabled bulk milk chiller is discovered to pave a new way for the industries to gain valuable insights, store the bulk data, improving efficiency, and in enhancing production.

Therefore, the existing traditional bulk milk chiller challenges will be resolved and improved products will be attained.

The bulk milk chiller is usually used in the dairy farm factories to store the milk in a consistent state, it is the large bulk containers that keep the milk in the good condition by maintaining it at the right temperature.

Therefore, it’s important to find out a smart system for the milk chillers and yes, it is possible with the IoT. The byteFACTORY provides the smart solution by using the IoT-enabled bulk milk chiller for the dairy units.

Let’s learn about the bulk milk chiller, its challenges, the IoT solution for bulk milk chiller, and its benefits.

Challenges with bulk milk chiller

The emergence of multiple innovations in the last decade has altered the business world, the use of a conventional system experiences multiple issues like maintaining a large volume of data insights, sudden fault, and monitoring the temperature, pressure, oil, and more. These issues need to be resolved.

Some common challenges are raised in the bulk milk chiller, they are,

- The compressor functions for longer periods and emits more warmth

- The discharge and evacuation pressures are both decreasing

- Condenser measurements are relatively modest

- Low ammeter values are produced by the compressor

- The temperature of the milk in the tank is higher than usual

- Inefficient in monitoring and storing the huge volume of historical data, operational data, and records.

Solution –Smart Connected Bulk Milk Chiller Using IoT

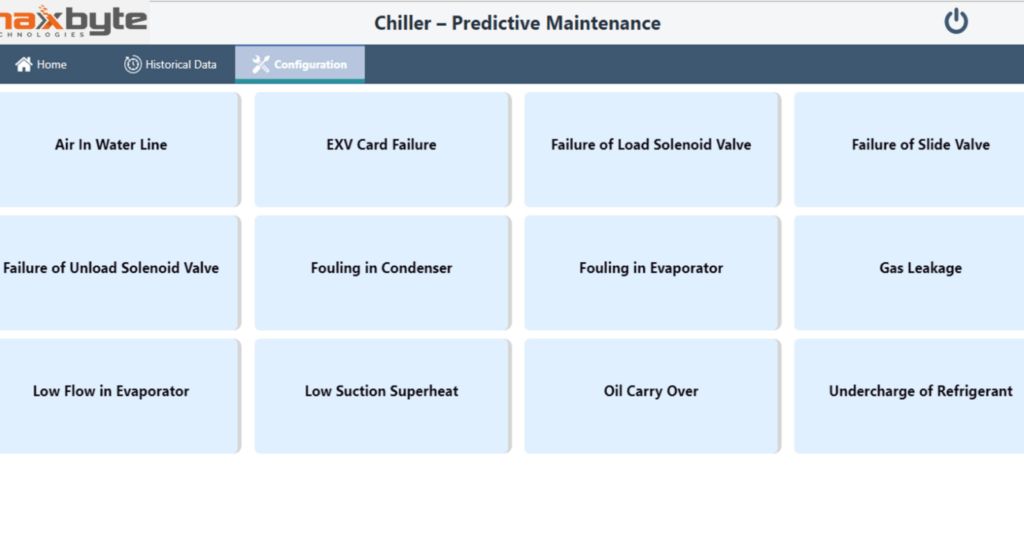

The Solution for the above issues is addressed with the IoT bulk milk chiller, the IoT has a greater impact on the milk chillers, prevention is better than cure, so Industrial chillers need to be monitored and the problems need to be diagnosed before they arise, so our IoT solution is here to sort out the issues.

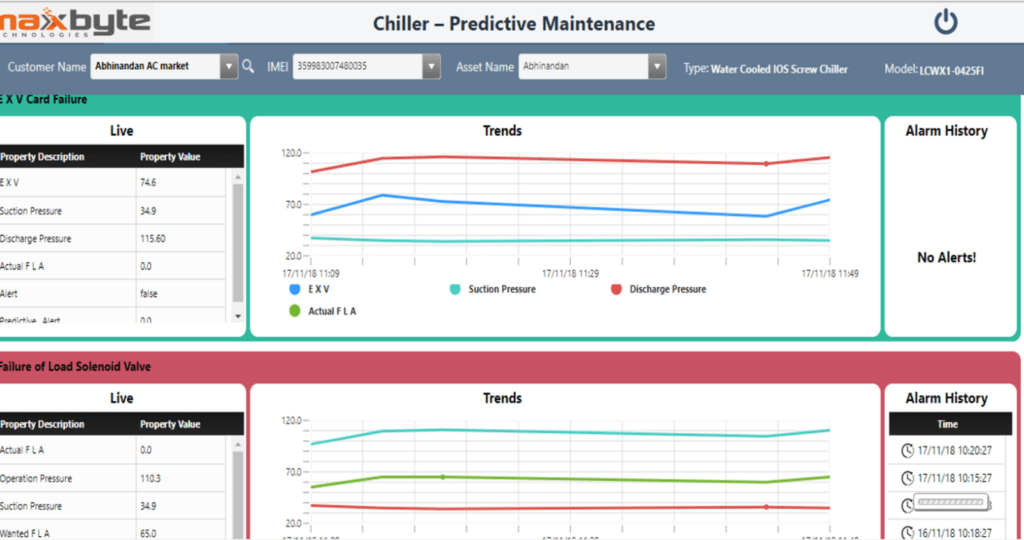

- The IoT enabled bulk milk chiller has a pressure sensor to detect the pressure-volume of the chillers, this pressure sensor monitors the flow of the fluid in the tank and sends the reports through cellular gateway (GSM/GPRS/4G) data transfer to the cloud server. So, with these pressure-based volume measurements, the industry supervisors/ operational managers can find out the measurement of temperature, milk level, and state of the bulk milk chiller via remote monitoring mobile applications, dashboards, visualizations, and data analytics.

The edge devices required for connecting the machines from the shop floor to the top floor can be purchased from the e-commerce marketplace.

- It also monitors the compressor, where the information is collected from the operating sensors (suction, temperature, pressure of oil) and also enables system administrators to regulate the compressor depends on a variety of supplementary data points for improving system control, increasing energy, speed, and uptime.

- The condenser is being phased out in favor of IoT-driven controllers, where it analyses numerous data and it modifies, controls the air, refrigerant supply to ensure that the system operates reliably and in practically any weather situation.

- With this smart system, the asset owner can also enhance the chiller performance by monitoring the evaporation, fluid flow control, air moisture, vibrations in the system, and more.

- It also assists the supervisors, if the working condition of the machines is in a bad state by sending alerts, sound notifications, messages, Mails.

- The bulk milk cooler is mostly used in the dairy farm manufacturing industries and this IoT enabled bulk milk cooler will be more useful for those industries.

In Maxbyte, we provide the diploma in industrial digitization to upskill all roles from shop floor to top floor in the manufacturing industry and efficient digitization implementation.

Expert services for your digital transformation solutions can be hired from a talent on-demand platform.

Features of IoT enabled bulk milk chiller

The features of using IoT enabled bulk milk chiller is

- Customized dashboards, reports

- Real-time data analysing and monitoring

- Enabling bulk milk cooler as a service business model

- Efficient system diagnostics by remote monitoring

- Efficient preventive maintenance & service planning.

Business benefits

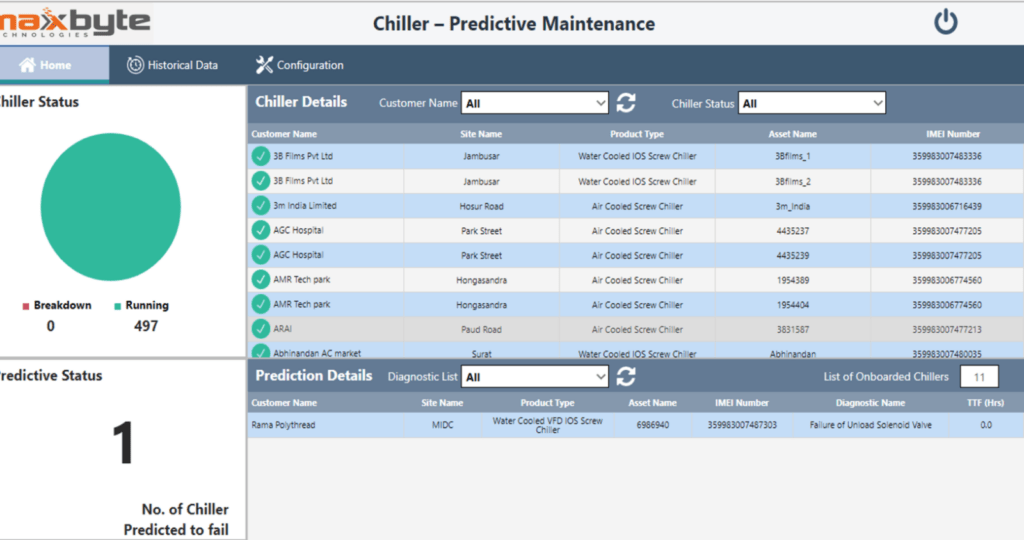

The benefits that the IoT bulk chillers providing are very immense right from transmitting the quality data to detecting the issues in the chillers.

- Continuous customer engagement

- Enhanced Operational Energy Efficiency

- Increased uptime

- Maintenance expenditures are reduced

Maxbyte has implemented this smart IoT solution for various industries and demonstrated business value to the customers, and also, customers started to realize their benefits.

To know more – Contact us or Book an appointment.