Every industries and segment in today’s world need two main adaptations: Digitization and Intellgentization. With the global competition increasingly growing, the need for fast adaption is one of the ever-changing market requests. Industry 4.0 is a promising approach based on the integration of technology and value. The applications of the general concepts on Industrial 4.0 are addressed by IoT and IIoT while forming a decentralized system in every single process. It is strategic initiatives that transform the digital culture and exploit every potential element in the new technologies across the globe. The paper aims to present and facilitate the concept of Industrial 4.0 with its goals and expansion over different segments. To put it simply, Industrial 4.0 is a steady and natural process of development in the production system. However, this is a rapid advancement in the technology and application that has consistently helped in increasing productivity.

From water and steam-powered machines to the Cyber-Physical , subsequent changes have been happening since the first Industrial Revolution. The digitized module of our conventional steam-powered machines is now less complicated, sustainable, and automatic. They promote persistence and work efficiently with supportive technology. The impact of Industrial 4.0 is depended on the value chain model where the production or the creating process that develops a new concept in the organizational; level. The complete value chain of the product life cycle is concentrating on individual customer requirements.

IoT is one of the most researched markets across the globe, and they are emerging to enable new business models like platform perspectives. However, the majority of the industries have started to transform the internal process while some of them have reached out in the customer service sector as well.

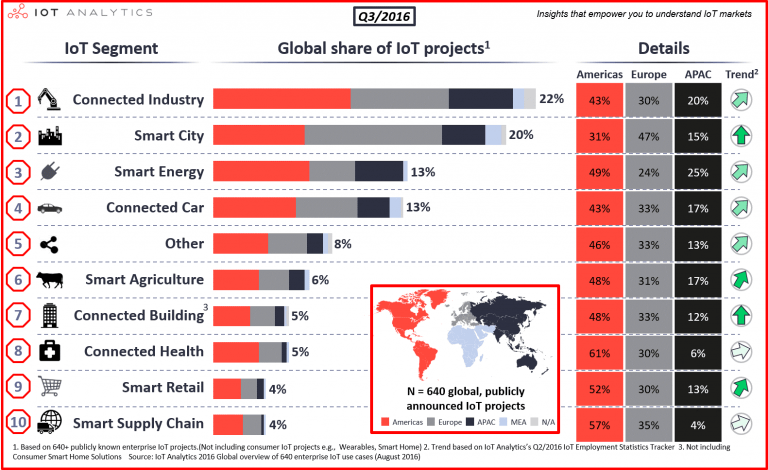

Smart City Projects(367 projects) is identified with the most number of projects while Industrial setting(26% Projects) sector has the second largest number of projects found. If you analyze them, geographically the USA makes the highest number in acquiring 45% of the IoT projects globally, followed by Europe with 35% and Asia at 16%. However, the segments and regions provide different statistical data. Because many of Smart City projects are located in Europe (45%). With the devices and equipment, North America is positioned at the top with 55% in the health sector and 54% of the Automobile sector. Asia is determinant in developing projects on agriculture.

In comparison with the 2016 data released by IoT analytics, we can find that Connected Industry has to be on the top list. While Smart city surpassed in 2018 but all the industries have shown significant growth in adapting to the IoT projects this year.

Scope of Analytics: Currently, 15% of the manufacturers are invested in Industry 4.0 technology. This will include large production and process facilities which are based on automation. However, in the next five tears this will grow up to 65%. The experts and the people from the field of IoT and IIoT are expecting that there is more to exploit the technology to reach greater benefits within 2025.

Elements of Industry 4.0:

Industry 4.0 is increasing with the high expectation, especially on the current IT infrastructure that enables the industries to adapt and at the same time being efficient quickly. Here are the four important elements that determine the efficiency with Industry 4.0

Horizontal Integration : There is a complex relationship between the operational goals and strategic development of the production system. It is always essential to develop an agile operational goal, while horizontal integration is the only way to achieve them. The industry gets to network with the world level value chain that helps in identifying various opportunities to understand the customer. Here value chain is described as the customer value that is created and captured. They are all interrelated set of elements that contribute to the company growth.

Vertical Integration: The company performance lies upon different synergy level that includes creation, development, and manufacture. They identify crucial areas in the administration; while observing them will help to evaluate several components that contribute to the growth of the company. They are mainly observed in two main parameters: Sociotechnical system and Value Creation Model.

Consistent Engineering: Here the full value chain will include starting from the suppliers until the process where the product reaches the customer. The end-to-end digital supply is made possible with the appropriate monitoring systems throughout the entire product life cycle. The intermediary steps are also recorded to improve the efficiency of each product.

People as Main Director of Value Chain: Industry 4.0 will enable a more direct model of creating personalize production and improve customer interaction. The servicing is the most important feature added to the system while the digital supply chain performs with the highest potential and at the same time reduces the cost of any intermediaries. The goal is to maintain the customer-centric approach by targeting value, speed, efficiency, and innovation

Technologies in Industrial 4.0:

System Integration: the systems are highly automated, especially with its operations. However, they struggle to communicate better with other systems. The standard open architecture in system integration will support in easy transfer of the information for both the company and the customer.

Big Data: Systems and process are highly increasing; hence, Industry 4.0 makes a great deal of data that can collect and analyzed. The challenges in terms of quantity and quality while analyzing the data are resolved. Big Data Analytics will fetch the performance of individual component; hence, you can tackle future production issues.

Simulation: Simulation can help us to asses various scenarios during the process of production — the system failure, assessing the equipment and performance, and identifying the problem area. Many companies have chosen simulation technology as it saves both time and money.

Internet of Things: It connects various physical devices and forms a network to acquire the data needed for making administrative decisions.

Cloud: It is mainly used for severing purposes where you can store the data and access them remotely. Industry 4.0 will witness the large shift in utilizing the cloud solutions for the betterment.

CyberSecurity: Security and reliability are the two important elements that are important for successful implementation of the digitized production process. Cybersecurity ensures that the data are safe and secure in the process and also during the transfer of data.

Autonomous Robots: Industry 4.0 is primarily focused on developing the intelligence that can upscale the level of performance while making the interaction with humans. It is targeted to understand the process, improve, and anticipate the efficiency of the company.

Jobs in Industrial 4.0:

Industrial 4.0 has improved great digital transformation across the global industries. Industry 4.0 will be embraced by many companies in the next ten years. This will increase the productivity and efficiency of the customer experience. The productivity improvements also include the conversion cost, cutting external material cost in the manufacturing industry up to 25 %. However, industrial 4.0 constantly encourages finding potential technology in motivating innovation, automation, and robotics. Machine to machine learning, human to machine learning is the most important trend when it comes to job function in the future.

Even though digitization and robotics have made remarkable advance with Industry 4.0, it does not take away the job as it is assumed to be. It needs to upgrade in the Job skill set to compete and overhaul the process in the industry. The focus in on integrating the interface to the job function from the scratch. World Economic Forum reveals that from 2015 to 2020, many of the core job skills will be diminished and there will be a remarkable transformation. By 2022 the first adopter of Industrial 4.0 will begin revolutionizing the competency

Decline and Rise: Since most of the jobs require additional or upgraded skillset, there are higher chances to lose the job in various sectors that include Installation and Maintenance, Construction and Extraction, Arts, Design, Entertainment, Manufacturing and Production and Office Administration

While many of the other application jobs such as architecture, computer and mathematics, management, Business operation, and sales will improve job vacancies. This proves that the individualized and self-centric jobs will decline. Every company needs a team that will work and executes the process of production together since everything is connected.

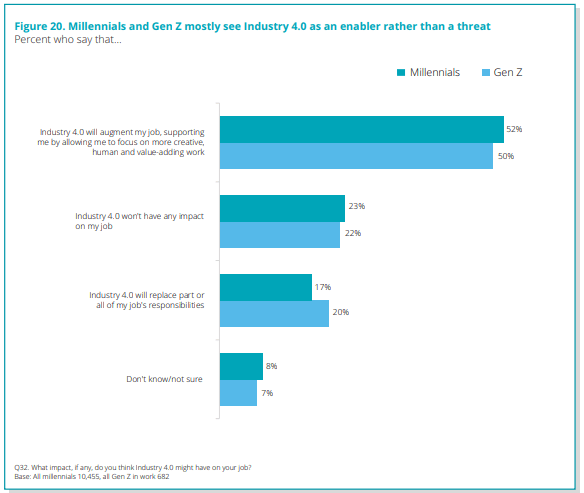

Millennial and Gen Z will recognize the current and future importance of Industry 4.0. However, many of them feel that they are not prepared for the changes in the industry. Even though they are adopters, there is a certain variance on how they will be able to accept the learning and training process. Three main resources help them to secure being part of Industrial 4.0

- Technical training: Employees here are trained by the organization or company. But this may occur only if the company is willing to offer such learning programs.

- Individual Training: One has to self-learn and taught in order to compete in the industry. Even 81% of the millennial feel Self-learning is the key success for adoption

- Institute: Many sill camps and companies rain the employees before they are part of any organization. This will help them to improve better while performing among the others in the industry.

Industry 4.0 – Readiness:

Gen Z and Millennial are ready to adopt the technology and learn from the various resources. While no platform is connecting the people with interest or matching the skill set. The institutes have the potential to teach the learners and similarly the industries. Three main functions help anyone to be prepared or ready for Industry 4.0

Competency: The competency level is rather a crucial part of getting well versed with the industry. This will involve a various process of learning. Self-Awareness and Learning are highly encouraged here. The competency levels include

Technology: The learner should always be open to adopt and get hands-on experience with innovation and technology. It is necessary that various technical aspects will fall as criteria for the job. The highest technology that people will look in for is the following, Control systems, Sensors & DAQ, Edge Analytics, Connectivity & Protocols, ICT Infra (On-prem / Cloud), IoT Platforms, A.I. Platforms, Immersive Technologies, Enterprise App Integration, Blockchain.

Behavior: Behavior is one of the main aspects to work in an organization that supports Industry 4.0. In 2015 the main agenda of the behavior pattern included ten elements, and the position of three main criteria has been re-positioned. Critical Thinking, Creativity is an Emotional intelligence has been mainly assessed, and that will determine your job.

Domain Specific: The industry 4.0 demands domain knowledge, where the human input integrates with the Analytical data. The Analytical data is automated and generated by the machines, and they vary with the human input. The opinion or the input given by humans will diminish, and the decision taken will be well informed. This will be mainly due to the analytics and performance gained in future events.

Task Management: Since machines and humans are going to work together, it is important for people to work efficiently. Hence Task management becomes a crucial role in the Job criteria. Especially the competency level is higher with Task management.

Innovation: By innovation Industrial 4.0 demands everyone to be critical and have a design approach while providing the solution for the problem. The design solutions are strategic, and the recurrence of the same problem is comparatively lesser.

Career: There is going to be the ultimate shift in the career which is seen when the skillsets are tuning. By 2022 there are following emerging global roles you can find. This data is released by the World Economic forum in 2018 Data Analytics and Scientists, AI and Machine Learning, Operations Manager, Software Application Developers, Sales and Marketing professions will flourish as a career option.

Research: Research is the third important function of Industry 4.0. There are 5 Key research priorities that the factory will look for growth and development. Agile Value Network, Excellence in Manufacturing, The Human Factor, Sustainable Value Networking, Interoperable Digital Platforms are some of the development as the outcome of the Research.

- Maxbyte Insights Team