Industrial Internet of Things (IIoT) has the primary objective to improve operational efficiency and digitize processes in industries. This will also help in streamlining and optimizing business processes, systems and devices especially the OEM product service and customer experience . There are currently over billions smartphone users in the world and the market analysis shows that the smartphone users will increase considerably in the years to come. IIoT solutions with mobile apps is logical and this makes them even more accessible. Also, there are more flexible platform for transmitting data compared to web apps. Mobile apps facilitates the remote monitoring, diagnostics and control of smart connected products using mobile device and wearable.

Following are the necessary mobile app modules for effective smart connected product.

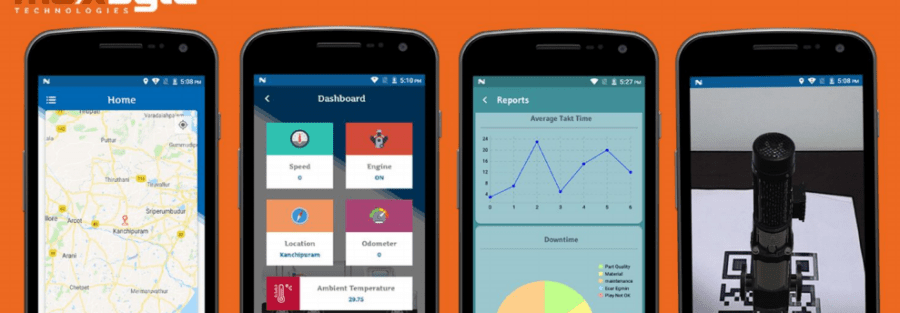

1. Geographic Information System (GIS): GIS captures, stores, analyses and presents geographical data. It is the technology that lets your smartphone, for example, display where a location is on a map. Real-time mapping and vehicle/equipment geo location tracking is a core feature of web and mobile apps across every industry. The idea is simple detect and stream location data to a live-updating map to smoothly watch location updates as they change in the real world. Equipment geo location tracking is an essential technology today.

2. Near Real-Time Dashboard: Dashboard is the act of collecting information from various near real-time data through various machines. Dashboard contains equipment general product details, customer details and sensor near real-time data like temperature, pressure, energy consumption, fuel level and etc.

3. Trends: Trends is used to tracks the machine temperature, pressure, engine level, etc in time series and more meaningful charts like line, pie, bar, etc., and tables. Trends has various way to filter the equipment data based on day, week, month and year.

4. Intelligent Maintenance System: An Intelligent Maintenance System provides data about the service status of equipment. Based on sensor input, IMS analyses the data and forecasts failures of these devices. The forecast failures can be used to improve the spare parts demand forecast results as the gathered condition monitoring information provides a more accurate prognosis about the status of the equipment. The enhanced demand forecasts in the next step build the foundation for planning the activities like inventory, transport, and maintenance management planning along a spare parts supply chain more adequately.

5. Alerts: Alert send alarms or notification of temperature, pressure, air level, machine warning and machine error status to several devices, such as Android, iOS, or a desktop PC based on sensor parameters thershold limits.

6. Augmented Reality: Augmented reality is a technology widely used in the gaming and consumer products industries, with many applications in industrial and other industries rapidly emerging. It aims at merging the physical and digital world. This means the actual grounding of digital objects into physical environments and interacting with them in the same way we interact with physical objects. AR is used for 3D technical manual of equipment service procedure, which shall be embedded in the mobile app for equipment service personnel efficiency.

We at Maxbyte Technologies incorporate efficient mobile app techniques for industrial OEM products and manufacturing problems. Want to know more about our mobility products and services? click here.