Every product goes through a life cycle that extends from its production up to its saturation. In order to get the best possible results out of your product at every stage of this cycle, a vital tool that can be used is the monitoring and diagnosis. Product monitoring and diagnosis help to keep the product on track and achieve the targets that you set. Product monitoring and diagnosis, unlike the other activities not specific to one particular phase or stage of the product life cycle. It is done from the beginning until the end of the product. These activities check whether the product is going as planned and whether there are any deviations from the prescribed plan of action. Let us now look at why it is so important to monitor and diagnose the various steps in the product life cycle.

The two steps of monitoring and diagnosis go hand in hand to implement a good product manufacturing and distribution setup. This is because aftermarket services help in to keep check if there are deviations from the expected results of the product. In order to better understand how this happens, let’s look at some of the best product monitoring and diagnosis practices and how they can help us.

The Best Practices for Product Monitoring and Diagnosis

You have to be able to control the product in order to create and deliver what you have in mind to the people. In order to do this, you need to continuously monitor it and keep checking it for deficiencies. By doing so the finished product or the end product will be exactly what you had planned for your business.

1.Measure your outcome:

At every step in the product life cycle, you need to check how you are performing. This gives you feedback on where you can improve and where immediate corrections need to be made. It also helps you prioritize your marketing and ad campaigns accordingly. How you measure your performance is dependant on the nature of your business and the product you sell. Performance need not always be evaluated based on profits.

2. Back up plans:

While you monitor and diagnose your product life cycle you may observe that there are some factors that keep changing and deviating from the plan. This cannot always be helped. In such cases, you may have to switch to a backup plan or a ‘plan B’. The development and implementation of an efficient backup plan is dependant on your monitoring the cycle. The more precise your diagnosis of the cycle, the right moment you find to put in your back up plan in action.

3. Make changes:

This step is quite self-explanatory though this is the step where most people seem to falter. Making changes can seem quite daunting especially if you have a particular plan of action all charted out. But with business being completely transient in nature and markets being unpredictable, change is something everyone should make peace with and implement whenever necessary.

4. Controlled changes:

While it is important to make changes, it is equally important to ensure that the changes being made are the right ones. Hence monitoring and diagnosis once again come in to play with the aim of gauging the impacts of the changes. Studying how changes can affect the various factors involved and the impact it creates can go a long way in minimizing risks.

5. Communication:

As in the case of all businesses communicating the decision you have made any changes you are making to all parties concerned is of prime importance. By backing your communication up with regular reports on monitoring and diagnosis, you are able to not only convince them on the need for these changes but also impart sufficient information as to the product cycle itself.

6. Choose the right changes:

While monitoring the product cycle can tell you that change is necessary, you may be provided with many different choices of change. It is up to you to pick the one that may actually help bring the plan back to track. Regular monitoring and diagnosis help you in this too as it can give you some pointers as to which factors influence non-desirable changes or behaviors. Following this, you are able to combat this with the changes that alter only the selected few variables.

7. Make predictions

In business, you must be able to predict various outcomes and prepare for all the eventualities. Monitoring and diagnosis of the product life cycle help you by predicting the outcomes of the impending stages that it will undergo. Following this progression, you may be able to identify quite precisely the outcomes and make long term as well as short term predictions for your business.

8. Customer trust

Building the trust of your customer is the primary factor that brings in brand value and profits for any business. Constantly monitoring and diagnosing your product and making the required changes can help convince the customer of your constant involvement in achieving better results. This also helps gain an insight into bridging the gap between customer needs and your product’s performance.

Being able to monitor how your product is performing and diagnosing its drawback eventually leads to better quality products. This helps maintain the quality standards expected of you from your clients. Thus it creates the best that could be available for your given budget setting you apart from your competitors in the market.

9. Risk assessment:

Every business has its own risks that can only be faced through careful planning and constant self-appraisal. The best possible tools available for such an appraisal for your business model is to monitor and diagnose the product life cycle. This helps you anticipate the risks and prepare strategies to respond to them much before the need ever arises.

10. Maintain reserves:

As with the case of risk management, keeping reserves is also necessary. When an unexpected situation arises, the reserves come in to save the project as well as avoid any delays. These reserves must not be stagnant but at the same time, it must be available when the need arises. By diagnosing your system, you can plan the amount of reserves that may be necessary. Monitoring gives you a rough idea on when you may need them with a little time to spare to make them available.

How byteService can contribute for the industry development?

Diagnosis and Analysis are the crucial part of the product life cycle. Hence, byteSERVICE introduced by MaxByte was launched with an objective of AFtermarketing service. It is highly impossible for any organization to imply a team to monitor all the equipment after submitting them to the customer. byteService help you to work on various aspects of monitoring the product through our SaaS systems. Check how our intelligence system help you to build a better organization

Intelligent Product Service System: The application can be accessed by various people who are working at the different levels. The changes made will be notified to all of the technicians involved in the process. You can also derive data from various equipments from the powerlab and combine them to analyze the overall performance. Most importantly you have access over all of them 24/7.

Real-time product monitoring and diagnostics: You can reduce the downtime by understanding the product variants that are configured from the customers through this application. You can easily identify and diagnose the services with the best response time.

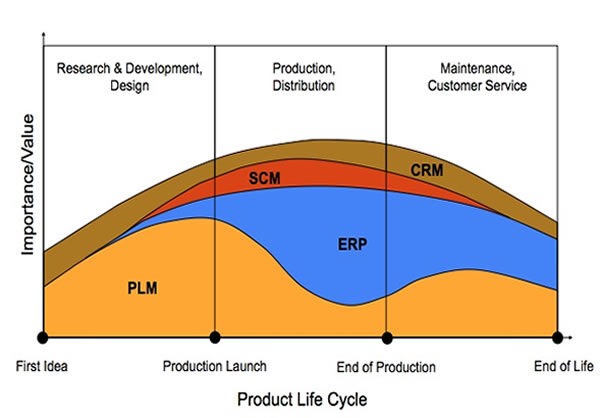

Enterprise Application Integration: With byteSERVICE you can integrated multiple third party applications such as CRM, PLM, SLM etx. WIth the push and pull technique you can always use the data to be integrated to the system.

Wrap Up:

With all these advantages being conferred by monitoring and diagnosis it is doubtless that it is an integral part of the project. By putting in place foolproof and hardy monitoring and diagnosis system, you are able to reach your target, maintain the necessary standards as well as stay prepared for any future consequences.

- Maxbyte Insights Team