The information revolution has led to the digital revolution which has completely transformed every aspect of businesses. The extent of digital transformation has been too vast and there is an imminent need to address the uncertainty arising out of the digital revolution as failure to do so can make an organization absolutely obsolete.

What is Digital Transformation & Digital Readiness

The term digital transformation refers to the adoption of digital technology to transform businesses. It is a profound process which involves business activities, competencies, asset capabilities, processes, and models to take full advantage of the opportunities provided by digital technologies such as cloud, industrial internet of things, artificial intelligence, data science, robotic process automation, block chain, etc. and use them in a strategic and prioritized way, keeping in mind the present as well as future organizational goals.

Digital readiness is the ease with which an organization and its employees can adopt the digital transition. For a smooth and complete transition of every aspect of its business to the digital mode, it is important that the employees of the organization are proactively trained. Since the employees are the foundation of any business, an organization must ensure that its staff members are onboard the digital readiness learning & career development program.

Challenges in Digital Transformation in the Manufacturing Industry

Digital technologies play a very crucial role in adding value to engineering, manufacturing, and aftermarket. It is important to see that organizations do not limit digital transformation to IT infrastructure and internet of things (IoT), but focus on digitizing every aspect of a business, from strategy to processes , lot-size-one, flexible manufacturing, green manufacturing and new business models link product as a service, etc. Such a huge shift may pose a number of challenges.

Any effort to digitally transform a manufacturing company will challenge the IT department and may require new release cycles, processes, and other innovations. Preparing the employees mentally for the transition so that they are willing to learn new digital skills is one of the biggest challenges for most companies. Budget and resource limitations may also be a serious challenge as the manufacturing industry is a very dynamic and cash-sensitive industry.

Questions in the Mind of Manufacturing Business Leaders on Digital Transformation

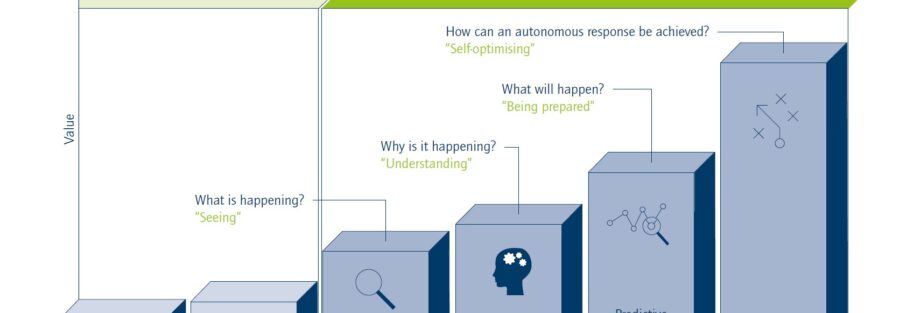

In today’s market scenario, there is a high demand to manufacture customized products with high quality, within short time spans and with optimum operational expenditures. These market scenarios are handled by data-driven manufacturing practices. With the advancement in digital technologies like IIoT, AI and low cost sensors, such data-driven manufacturing practices will enable transparency and predictability for proactive actions and effective decisions using various valuable data insights available across manufacturing processes.

So to enable data-driven manufacturing, there are five key questions Business Leaders may have:

1. Where does a manufacturing company start its digital transformation journey?

2. What are the digital capabilities of machines, materials, methods and humans?

3. What are the technologies to be used for digital manufacturing?

4. What would be the return on investment on a digital transformation roadmap?

5. Who could be the technology partner to jointly define, systematically transform and demonstrate the business value as well as successfully deliver solutions along the journey?

The best way to get right answers to all the above questions is through a digital readiness check or structured assessment process.

Digital Readiness Assessment in Manufacturing

A digital readiness assessment is the process of systematically evaluating and analyzing a company’s ability to adapt to digital changes.

In general, digital readiness assessment for a company generally covers six areas – strategy, customer, competition, employees, organization and technology. Each of these areas is systematically analyzed and tested on various parameters and the scorecard, thus, obtained can be used to assess their digital maturity.

Strategy: This is to determine if the organization has a systematic digitalization strategy and if the management fully understands the strategy. Companies often lack an understanding of digitalization in practice which leads to rolling out of hasty and poorly planned digitalization measures. Such measures do not contribute to the efficient digital development of the organization leading to wastage of time and resources.

Customers: This involves identification of (digital) customer requirements. Market and customers are the two factors which greatly influence successful digitalization, especially in the areas of sales and customer relationship management. Companies are also required to have a flexible digitalization approach corresponding to the ever changing customer behaviour. Evaluation of (digital) customer requirements is, therefore, an important parameter for assessing digital maturity.

Competition: In today’s competitive market where numerous new digitally-oriented competitors are entering the market and existing competitors are also equipping themselves with latest technology, it is crucial to study and determine the digital maturity of the main competitors, especially with regard to sales.

Employees: The purpose of the digital readiness assessment is to test how able and willing the employees of an organization is to shift to the digital culture. The digital world is continually changing at a very fast pace. Companies often fall back on new and young talent to face this problem. However, organizations fail to realize that they don’t need new talent but they need employees who have the will and ability to adapt themselves to the technological changes.

It is necessary for companies to assess their employees and help them transition to the digitalization mode. Organizations must also identify the true potential of their employees and help them update by offering adequate training and skills.

Organization: Evaluation of the digital maturity of the organizational structure as well as the existing digital know-how. In order to have a successful digitalization strategy, there must be appropriate roles and responsibilities in the company to handle the digital infrastructure, e.g. a Chief Digitalization Officer (CDO). It is also essential to have the right digital know-how. Digital maturity assessment helps in determining the company’s maturity on these two parameters.

Technology: This includes assessment of the existing technology in various core functions of the company such as finance, sales, HR engineering, manufacturing, aftermarket, service, and internal communication etc. This is needed in order to determine which digital technologies are already in use and which areas lack the right technology.

Each of these areas is evaluated individually to determine the overall digital readiness level of the organization.

Digital Readiness Check Tool by Maxbyte

Industrial Enterprise or product lifecycle digitization readiness check is an assessment tool developed by Maxbyte Technologies. From Maxbyte experience with 40+ global digitization system integration, byteFACTORY product deployment, Industry 4.0 Accelerator Program and more than two hundred market analysis with Manufacturing Business Leaders Maxbyte have come up with the Maxbyte Industrial Digital Readiness Tool Kit.This is a free tool which involves a simple 10- minute survey.

Completion of the survey will provide you with a high level assessment report of your organization’s readiness to adopt digital.

The following are the benefits that you stand to get from the Maxbyte Industrial Digital Readiness Tool Kit:

1. Understand organization’s current digitization maturity level

2. Learn the global standards in digitization

3. Identify the gaps to be on par with global digitization standards

4. Prioritize the use cases based on organization’s requirement

5. Helps to prepare business case with expected ROI

6. Helps to create digitization road map for next 3-5 years

7. Help prepare for deploying enterprise wide digital solutions

This assessment tool helps manufacturer to get prepared for a structured digital manufacturing transformation of their organization and achieve successful business value outcome.