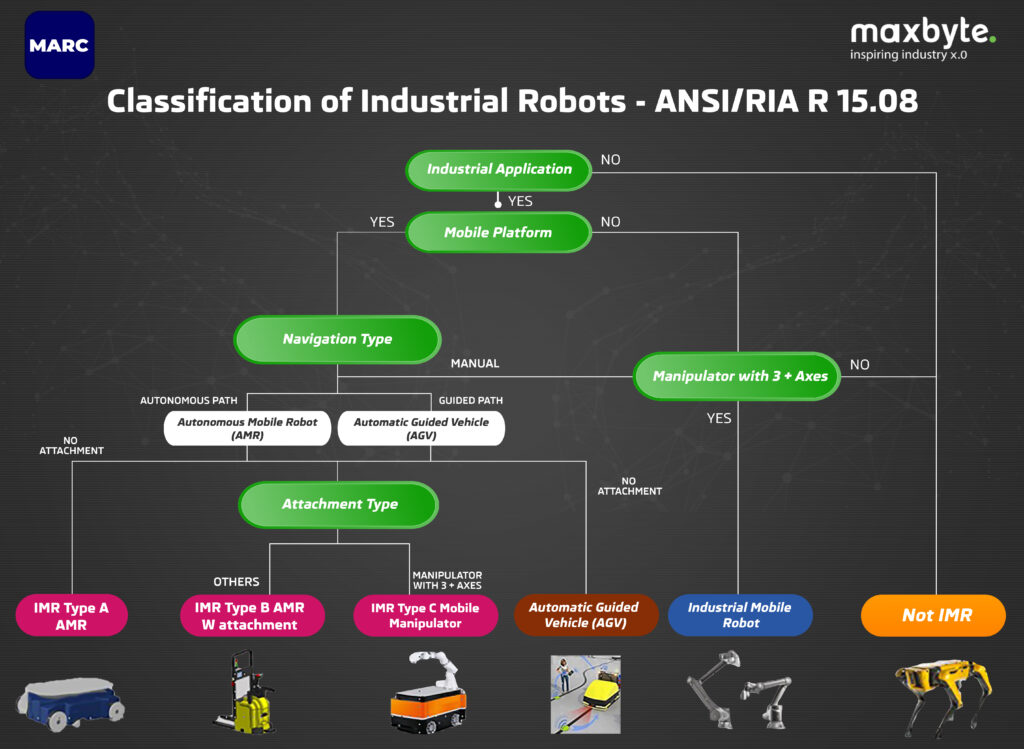

Traditional robots which are otherwise known as PICK AND PLACE ROBOTS OR cobots are in use in manufacturing industry right from the 1970s. ABB, FANUC, Denso, Kuka and off recent universal robots have all penetrated deep into Industrial Automation and are mainly used for material loading / unloading, welding, painting, assembly operations etc. Robotization of Intra company logistics is a growing space of Industrial robotics. It is even estimated that by 2022, the rapidly growing autonomous mobile robots (AMR) space will start to overtake the traditional industrial robotics market, and of the 8 million robots forecast to be shipped in 2030, nearly 6 million will be mobile, according to ABI Research. With this rapid growth, Robotic Industries Association (Now Association for Advancing Automation) along with ANSI has framed the latest standards for Industrial Mobile robots under ANSI RIA R15.08. In this the clear classification of industrial robots is provided. Let us see this overview.

Classifications of the industrial robots based on the ANSI/RIA R15.08:

The industrial robots play the major role in increasing the productivity in the industry. The responsibility of the industrial robots is mostly in the field of assembling, inspection, material movement, manufacturing, robotic welding and logistics. The various industrial robots come under the safety standards of the ANSI (American National safety Institute) / RIA (Robotic Industries Association) R15.08.

Autonomous Mobile Robots (AMR)

The Autonomous Mobile Robots (AMR) can be implemented in any place without fixing any feedback system in the working environment and without changing any of the existing setup. The Autonomous Mobile Robots (AMR) is a plug and play solution for any of the suitable use case. The device has its own default navigating system based on the laser and proper feedback system using the Inertial Measurement Unit (IMU) also implemented as a default setup. By using the laser data and the feedback system the AMR system can find its own optimum path to reach the destination without collision with the obstacles.

Industrial Mobile Robots (IMR) Type A

Type A Industrial Mobile Robots (IMR) is designed in such a way that it can act and function as an independent system, without making changes in the working environment. The 2D layout of the working environment has to be fed to the system and by using the laser data and the IMU (Inertial measurement unit) data the vehicle can find its own optimum path and can reach the destination. The additional features such as BMS (Battery Management system), FMS (Fleet Management system), Vision system, Auto charging system etc. can be integrated with the autonomous system. The Type A Industrial Mobile Robots are a plug and play devices, the initial work that has to be done for the Type A IMR is that the 2D layout of the working environment has to be fed to the IMR by using the laser scanning method or the layout has to be uploaded in the controller. By using the layout and the laser scanned data the IMR can function independently in the working environment. Maxbyte has the MARC A500 robots under this category which operate without any attachment for carrying loads to cater to the needs of industrial intra logistics.

Industrial Mobile Robots (IMR) Type B

The Industrial Mobile Robot Type B is similar to type A, the additional feature that, is has the capacity to make any manual movement machines such as forklift, pallet truck, cleaning machines etc. can be converted into autonomous machines by integrating the manual machines with the autonomous systems. Only the autonomous system will be mounted on the manually operated vehicle and it can be converted into fully autonomous vehicle. Also, an advanced feature that the IMR type B has that, it can be made it to run in manual movement as pervious at any time by using the auto/manual operation. The auto/manual operation will be achieved by using the bypass method such that while the AMR is running in the autonomous mode, the manual operating system will not be functioned and while in operating in the manual mode, the autonomous operating systems will not be functioned. Maxbyte has built AX platform which helps with robotization of industrial vehicles such as battery-operated pallet trucks, fork lifts etc. and these fall under Type B.

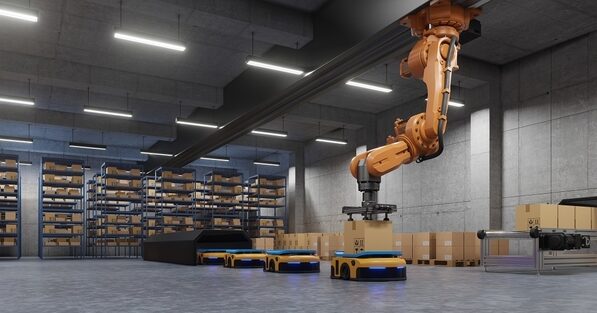

Industrial Mobile Robots (IMR) Type C

Type C IMR is also similar to the Type A, it can also function as an independent system by without disturbing the existing working area. Additional to this any additional add-on setup can be done on the platform of this IMR. The add-on setup can be a mobile manipulator, robotic arm, Cobot or any actuator setup can be done on the IMR. By using this vehicle and the add-on setup, various works can be done by navigating the vehicle to the required destination and the add-on can do the respective works in various locations. Such that the various manipulators can be replaced with one manipulator and same operation can be achieved with single manipulator. This Type C AMR can be used in many applications such as inspection, pick and place, material transportation, machine tending etc. Various works also can be achieved by using one mobile manipulator place on the Industrial Mobile Robots. The add-on is fixed is such a way that it can be powered and controller with the default system and it can be removed, and similar add-on can be fixed without affecting the existing system. Maxbyte’s A500 platform supports multiple attachments and one such case is mounting of Cobot arm to support industrial inspection and visualization scenarios.

Industrial Mobile Robots

The industrial robots are focused on the production, manufacturing, assembling, inspection by reducing the man power. The key role of the industrial robots is that it has to act based on the command or it has to repeatedly to do the work that has been fed initially by the controller. The industrial robots don’t have the independent system, it has to be functioned as a dependent system. The industrial robots can do the repeated works with good precision and accuracy than the human and in a rapid manner. They have a fixed base location which itself can be moved by manual processes. They have different axis of movement with an arm like structure majorly used for applications such as pick and place, welding, painting, digital quality inspection etc.

If you want to know more about AMR and how MARC products can help you or your company please reach out to us.Autonomous Mobile RobotsSmart FactoryShare on Facebook

1 Comment

lasixJex

I am not sure where you’re getting your information, but great topic. I needs to spend some time learning more or understanding more.

Thanks for great information I was looking for this information for my mission.